Trigonox® B is an efficient initiator for the production of Low Density Polyethylene (LDPE). It is used both for tubular and autoclave processes. In most cases a combination with other peroxides is used to ensure a broad reactivity range. Trigonox® B may also be used for the polymerization and copolymerization of styrene in the temperature range of 95-185°C. In practice,

combinations of two or more peroxides with diverging activities are used to reduce the residual monomer content in the final polymer and to increase reactor efficiency.

| Active oxygen | ≥ 10.83 % |

| Appearance | Clear liquid |

| Assay | ≥ 99.0 % |

| Color | ≤ 30 Pt-Co |

| Inorganic + organic hydrolysable chloride | ≤ 100 mg/kg |

| TBHP | ≤ 0.099 % |

| Density, 20 °C | 0.800 g/cm³ |

| Viscosity, 20 °C | 0.9 mPa.s |

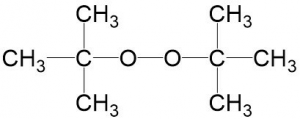

Trigonox® B (Di-tert-butyl peroxide) can be used for the market segments: polymer production, polymer crosslinking and acrylics production with their different applications/functions. For more information please check our website and/or contact us.

To make chemical sourcing more efficient reliable, and intelligent

Every process of our packaging is very strict

just to betterdeliver the goods to your hands!

Trigonox® B is an efficient initiator for the production of Low Density Polyethylene (LDPE). It is used both for tubular and autoclave processes. In most cases a combination with other peroxides is used to ensure a broad reactivity range. Trigonox® B may also be used for the polymerization and copolymerization of styrene in the temperature range of 95-185°C. In practice, combinations of two or more peroxides with diverging activities are used to reduce the residual monomer content in the final polymer and to increase reactor efficiency