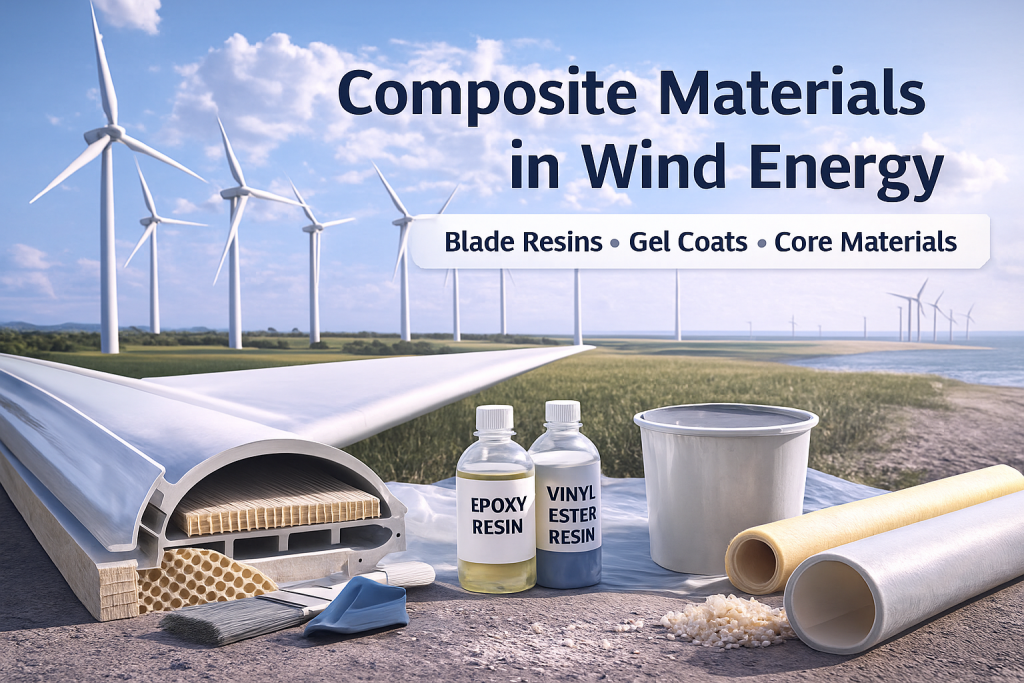

As global renewable energy expansion accelerates, wind power remains one of the fastest-growing segments—pushing the demand for advanced composite materials to new heights. In 2025 and beyond, the performance of wind turbine blades depends heavily on the industry’s progress in resin chemistry, surface protection systems, and lightweight reinforcement materials.

This article explores the core composite materials used for modern wind turbine blades, their role in structural performance, and the market trends shaping future procurement decisions.

Why Composites Dominate Wind Turbine Blade Manufacturing

Wind turbine blades must deliver three critical characteristics simultaneously:

- High strength-to-weight ratio

- Long-term fatigue resistance

- Superior weather and UV durability

Conventional materials such as steel or aluminum cannot meet these requirements. Composite materials—specifically fiberglass, carbon fiber, vinyl ester resins, epoxy resins, gel coats, and lightweight core materials—have therefore become the industry standard.

The result is a material system capable of enduring decades of exposure to mechanical loading, saltwater, humidity, and extreme temperature changes.

Blade Resins: Vinyl Ester vs Epoxy

Vinyl Ester Resin: the Workhorse for Cost-Effective Blades

Vinyl ester resin (VER) has long been preferred for:

- High chemical resistance

- Excellent mechanical performance

- Faster curing cycles

- Better tolerance during manufacturing

It remains widely used in wind blades ranging from mid-size to utility scale. The material’s balance of cost and performance makes it ideal for resin infusion and hand lay-up processes.

Epoxy Resin: Preferred for High-End, Large Rotor Blades

For turbines exceeding 5 MW and offshore installations, epoxy resin systems dominate due to:

- Superior fatigue resistance

- Greater bond strength

- Lower shrinkage during curing

- Higher thermal stability

The industry shift toward longer blades—now exceeding 120 meters in length—continues to drive strong demand for high-performance epoxy resin systems.

Gel Coats: Protecting Blades Against Harsh Environments

Wind turbine blades face continuous exposure to:

- UV radiation

- Rain erosion

- Salt spray

- Sand abrasion

- Temperature fluctuations

To ensure long-term durability, advanced gel coat systems play a vital role. These coatings create a protective barrier that:

- Prevents moisture intrusion

- Enhances UV resistance

- Reduces surface cracking

- Extends blade service life

Modern gel coats for wind blades emphasize flexibility, anti-erosion performance, and excellent adhesion to both VER and epoxy laminates.

Core Materials: Lightweight Strength for Massive Blades

As blades grow longer, reducing weight without compromising strength has become a top priority.

Common core materials include:

Balsa Wood

- High compressive strength

- Good fatigue performance

- Natural and sustainable

PVC Foam Core

- Excellent impact resistance

- Easy to machine

- Attractive cost-performance ratio

PET Foam Core

- Increasingly popular for sustainability

- Recyclable and thermally stable

The combination of lightweight foam cores + fiberglass reinforcement + high-strength resin systems enables blade manufacturers to achieve the optimal balance between stiffness and weight.

Market Trend: Offshore Wind Drives High-Performance Composites

Global offshore wind installations are expected to grow sharply over the next decade, driven by:

- Larger turbines (12–20 MW)

- Longer blades

- Harsher operating environments

This shift is increasing the consumption of:

- Carbon fiber reinforcements

- Epoxy resin infusion systems

- Advanced erosion-resistant coatings

- High-density structural foam cores

Suppliers who can deliver consistent quality, stable supply, and advanced resin formulations will be best positioned to serve this evolving segment.

Digital Procurement: Simplifying Composite Material Sourcing for Wind Energy

As wind turbine manufacturers scale production, digital B2B procurement platforms are becoming a key resource for sourcing composite materials more efficiently.

Thousands Technology – Your Digital B2B Store for Composite Materials

Thousands Technology provides a streamlined, modern way to source wind energy materials such as:

- Epoxy resins

- Vinyl ester resins

- Gel coats

- Fiberglass reinforcements

- Additives and curing agents

Why buyers choose Thousands Technology:

- Direct supply from vetted manufacturers

- 100% self-operated & authenticity guaranteed

- Full after-sales support

- Faster comparisons and real-time availability

Whether you are manufacturing blades, nacelle components, towers, or composite substructures, Thousands Technology simplifies your procurement with a trusted digital marketplace.